INSERTS INTERNATIONAL

Ultrasonic Brass Molded Inserts

Through the company’s historic dedication to provide the best customer service possible, Inserts International has developed a true expertise in meeting customer expectations. Past experience with numerous custom designs allows Inserts International to offer time savings and the best solution for your production through collaborative design..

Inserts International also offers you a wide variety of additional custom insert plating and material options, including zinc plated and gold plated inserts.

| Plated Inserts Available: | Materials Available For Inserts: |

| Zinc plated inserts Gold plated inserts Brass plated inserts Nickel plated inserts Copper plated inserts Chrome plated inserts Others on request |

Brass Steel Aluminum Stainless steel Copper/bronze Others on request |

Colored Inserts

Uses for Colored Inserts:

- Inserts with similar appearances

- Two same inserts with different measurement systems ( inches & metric)

- Two same inserts with different destinations (inside, outside the product, ...)

- The assembly order process (blues first, then reds,…greens, ...) for you or your final customer

The benefits of colored manual inserts include savings in production, simplifying complex assembly processes, and reducing assembly and maintenance time, all resulting in higher quality and default-free rates. Watch your final customers satisfaction levels increase. The extra measure of insurance you gain is invaluable.

Colored Manual inserts are immediately available in Red, Blue, Green, or Black.

Standard Ultrasonic Brass Insert Details

Inserts International's standard and custom ultrasonic brass inserts are utilized in a wide range of products (electronics, automobiles, tools, ...) and can be installed in a variety of installation types and base materials.

The four main types of insert installation are:

- Manual or Press-in: The insert is pressed into the drilled "boss" or remolded hole, using a standard press.

- Heat-Stake: The insert is pressed into the mounting “boss” hole, using a thermal press, whose heat melts the plastic during the insertion. The plastic then solidifies to lock the insert into the mounting hole.

- Ultrasonic: A high frequency vibration is applied while the insert fastener is pressed into the mounting hole. The vibration creates heat that melts the plastic during the insertion. The plastic then solidifies to lock the insert into the mounting hole.

- Molded-in: The insert is placed on core pins in the mold and the part is formed around it.

The main base standard insert materials are:

- Hard thermoplastics: PA-filled, PC/ABS Blends, PPS, PBT

- Medium thermoplastics: ABS, PA-unfilled, POM (Acetal), PVC

- Soft thermoplastics: PP, PE, HDPE

- Thermosetting plastics: BMC, DMC, Phenolic, Polyurethane, SMC, Tufnol, Ureas

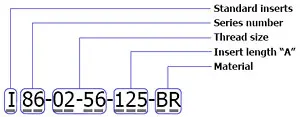

Standard Inserts Selection Table

| Inserts International Part Number | Installation Type | Base Material | Advantages | |||||

| Manual | Heat Stake | Ultra-sonic | Hard thermo plastic | Medium thermo plastic | Soft thermo plastic | Thermo-setting | ||

I40 |

|

|||||||

I41 |

|

|||||||

I42 |

||||||||

I43 |

||||||||

I46S |

|

|||||||

I46L |

||||||||

I55 |

|

|||||||

I64 |

||||||||

I72 |

|

|||||||

I77 |

||||||||

I85 |

|

|||||||

I86 |

|

|||||||

I87 |

|

|||||||

I88 |

|

|||||||

I90 |

|

|||||||

I92 |

|

|||||||

I93 |

||||||||

For more information or product pricing, contact Bolt Products today!

|

Part Look up |

|

|